Introduction

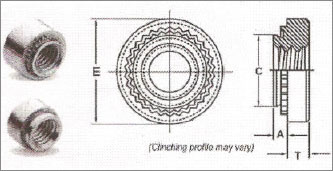

Installation of self clinching nuts is simple, quick and convenient just insert them in punched or drilled holes and then apply a squeezing force to embedded the clinching ring completely in the sheet metal. The clinching ring locks the displaced metal behind the tapered shank, ensuring high push out resistance. High torque out resistance is ensured when the knurled platform is embedded in the sheet metal. All clinching takes places on one side of the sheet and the reverse side remains flush and smooth.

All dimensions are millimeters

| Thread Size x pitch | Type | Thread Code | Shank code | A (Shank) Max | Min sheet Thickness | Hole size in sheet + 0.08 |

C. Max | E +0.25 | T + 0.25 | Min Dist Hole C/I To Edge |

|

| Fastners Material | |||||||||||

| Carbon Steel | Stainless Steel | ||||||||||

| M2 x 0.4 | KS | KCLS | M2 | 0 | 0.77 | 0.8-1 | 4.25 | 4.22 | 6.3 | 1.5 | 4.8 |

| 1 | 0.97 | 1 | |||||||||

| 2 | 1.38 | 1.4 | |||||||||

| M2.5 x 0.45 | KS | KCLS | M2.5 | 0 | 0.77 | 0.8-1 | 4.25 | 4.22 | 6.3 | 1.5 | 4.8 |

| 1 | 0.97 | 1 | |||||||||

| 2 | 1.38 | 1.4 | |||||||||

| M3 x 0.5 | KS | KCLS | M3 | 0 | 0.77 | 0.8-1 | 4.25 | 4.22 | 6.3 | 1.5 | 4.8 |

| 1 | 0.97 | 1 | |||||||||

| 2 | 1.38 | 1.4 | |||||||||

| M3.5 x 0.5 | KS | KCLS | M3.5 | 0 | 0.77 | 0.8-1 | 4.75 | 4.73 | 7.1 | 1..5 | 5.6 |

| 1 | 0.97 | 1 | |||||||||

| 2 | 1.38 | 1.4 | |||||||||

| M4 x 0.7 | KS | KCLS | M4 | 0 | 0.77 | 0.8-1 | 5.4 | 5.38 | 7.9 | 2 | 6.9 |

| 1 | 0.97 | 1 | |||||||||

| 2 | 1.38 | 1.4 | |||||||||

| M5 x 0.8 | KSS | KCLSS | M5 | 0 | 0.77 | 0.8-1 | 6.4 | 6.38 | 8.7 | 2 | 7.1 |

| 1 | 0.97 | 1 | |||||||||

| 2 | 1.38 | 1.4 | |||||||||

| M6 x 1 | KS | KCLS | M6 | 00 | 0.89 | 0.92 | 8.75 | 8.72 | 11.05 | 4.08 | 8.6 |

| 0 | 1.15 | 1.2 | |||||||||

| 1 | 1.38 | 1.4 | |||||||||

| 2 | 2.21 | 2.3 | |||||||||

| M8 x 1.25 | KS | KCLS | M8 | 1 | 1.38 | 1.4 | 10.5 | 10.47 | 12.65 | 5.47 | 9.7 |

| 2 | 2.21 | 2.3 | |||||||||

| M10 x 1.25 | KS | KCLS | M10 | 1 | 2.21 | 2.31 | 14 | 13.97 | 17.35 | 7.48 | 13.5 |

| 2 | 3.05 | 3.18 | |||||||||